Rubber Roofing

Roofing specialists at your service …

EPDM Rubber Roofing

EPDM roofs are rubber-like materials that provide protection from ultraviolet rays, water damage and other weathering factors like hail. It’s important to typically need repairs for EPDM Roofs due to fading out in color over time as well as cracks in the material where ice can build up during winter months which will lead to more cracking on the surface of your EPDM Roof after spring thaw occurs.

The material of this roof type is considered a foam rubber product, which means it’s not as durable or resistant to environmental factors such as sun damage from UV rays and needs regular repairs if there are any pealing spots that have become porous or brittle due to the sun. The material is made of polymers which are sensitive to extreme heat and cold – if you’re in an area where the temperature fluctuates a lot, make sure your roof can withstand these changes too so repairs will be needed periodically. EPDM roofs are most commonly found on commercial buildings since they need to resist changing temperatures.

Newcastleroofers

Rubber Roofing Membranes

Rubber roofing membranes are made of a synthetic rubber material with additives to resist ultraviolet degradation; the same type of elastomeric materials used in production car tires because they offer good resistance against wear, tear and aging. Rubber roofs provide excellent protection from hail impacts that could damage asphalt shingle roofs or make other types brittle.

These advantages make them suitable for low-slope commercial buildings such as those found on retail malls where there is little risk from wind uplift (they can be installed over any new deck) and high impact weather conditions including hail storms and hurricanes. The membrane offers better watertightness than many other roof systems which makes it a preferred choice for area below ground level like garages, parking areas and entrances.

Other advantages of rubber roofing membranes are that they are easily installed by roofers and usually require little maintenance.

The disadvantages of rubber roofs include cost, which is higher than for other roofing materials; their susceptibility to stretching in hot weather with consequent cracking if the membrane is not maintained properly; and its inflexibility when it comes to overlaying a new system on an existing one. The material cannot be used where there is too much wind uplift or rain water runoff problems either.

Disadvantages of rubber roofing are the same as other roofs: they require periodic maintenance to remain in good shape. They also don’t provide any fire protection for buildings or vehicles because it is not designed for insulating purposes. However, this type of roof will maintain its aesthetic appeal over time with regular cleaning by means of pressure washers; which may be a desirable attribute if aesthetics areru important considerations during construction selection process.

The durability and ease of maintenance are the primary advantages to this roof type, with a complete warranty against deterioration for up to 40 years. The rubber roofs provide no fire protection because they do not provide any insulation properties; as such, there is an increased risk in buildings or vehicles from fires spreading if the roof catches on fire (especially when compared to other types of roofs).

This roof is more resistant than many others to high winds including hail storms and hurricanes due to its ability withstand impact without leaking significantly which can be desirable for some building owners who may have strict requirements related with wind uplift resistance during construction selection process. This material also provides better water tightness than most other roofing materials that reduces the likelihood of leaks over

Rubber roof membranes are usually installed on top of a roof deck or on the top side of insulation foam.

The membrane is usually made from synthetic rubber processed to be flexible enough to seal out water and prevent wind-driven rain from penetrating below it into the building interior, but strong enough not to stretch too far when exposed to hurricanes which means that their life span can vary significantly depending on environmental conditions (like high winds). This roofing type has excellent sound absorption properties; as such, this may not be desirable for those who enjoy living in silence. On top of these benefits, this roof also features natural fire resistance.

Rubber Roof Coatings

Rubber roof coatings are made from 100% recycled rubber with no additives or fillers added to it. It is considered one of the greenest types because it does not use up natural resources like petroleum products do.”

Considerations to be made in choosing rubber roofing shingle coatings include installation costs, the type of roofing that is currently in place and what degree of sound insulation is desired.

Rubber roofing shingle coatings provide great insulation from noise pollution like traffic or construction work. They also offer a natural fire resistance with increased durability, although this can vary depending on the thickness and quality of the rubber product used.”

Their disadvantages include an increased chance for leaks if not installed correctly and cost-prohibitive installation price without proper preparation.

Application considerations are whether one wants to apply it as shingles or tiles; there may be additional labor charges incurred when installing certain types of roof coverings.

Rubber Roof Sheets

Rubber roof sheets can be used for roofs with slopes from 0 to 25 degrees as well as roofs that have no slope at all. Rubber roof sheet systems consist of a double-coated rubber membrane laminated between two layers of polyester fabric and might also include an insulation layer on cold roofs. These roof sheets typically require seam sealant tape and flashing seals around penetrations like vents, skylights, chimneys, pipes etc., but not underlayment boards or any additional base material such as felt paper.

Rubber roof sheets are different from rubber shingle coatings which are a liquid applied coating that is painted onto roofing, metal roofs or asphalt shingle roofs. The rubber shingle coatings change the appearance of these types of roof coverings while rubber roof sheets do not.

The main advantage to using rubber for your roof is its ability to provide watertight protection without concern about underlayment boards and additional base material such as felt paper. This makes it an excellent choice for flat, low-sloped roofs with no penetrations like vents, skylights chimneys etc., but they also work well on sloped surfaces too

Newcastleroofers

Contact Us

We understand that a flat roof is a significant investment, and we're here to support you every step of the way. That's why we've made getting in touch with us as easy as possible.

Our Office

IPX Roofing Services

Newcastle upon Tyne, England, NE1 8, GBR

Open Office Hours

M-F: 8am - 6pm

S: 10am - 4pm

S: Closed

Get in Touch

newcastleroofers.co.uk

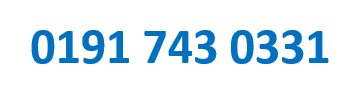

0191 743 0331

Prefer to write to us? No problem. You can send us an. We aim to respond to all emails within 24 hours.

hello@newcastleroofers.co.uk